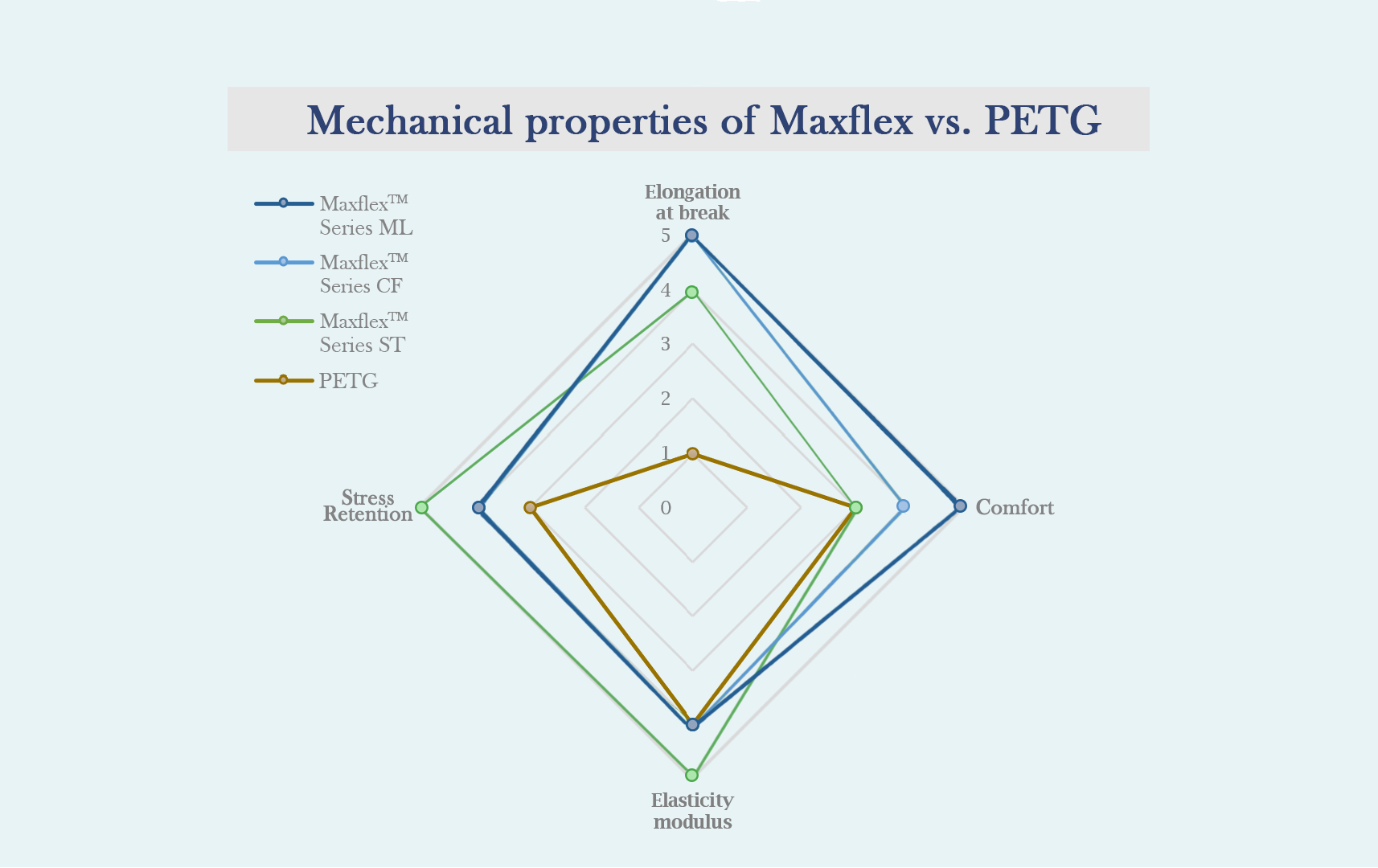

Ultra high hardness thermoplastic polyurethane material(TPU) with high stress retention, can create a good correction effect.

At the same time, this series of products have good tear resistance, good toughness, can be better for blister forming to achieve the best clinical correction function.

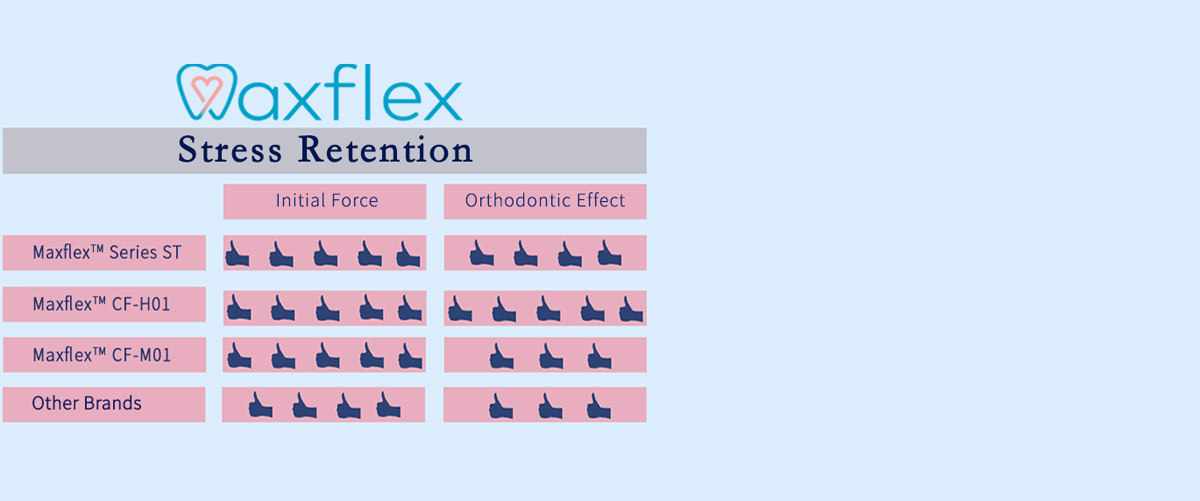

This series of Maxflex™ materials provide the highest stress maintenance performance. According to the experimental results, the stress holding force of this series can maintain the effect of more than two weeks at least.That means it gives the best corrective effect.